One of the easiest ways to reduce incidence of hydrogen sulfide development is by making specific nitrogen adjustments during primary fermentation. As mentioned in the last blog post, poor nutrient management can also lead to stuck fermentations.

Years of research has shown winemakers that a must’s starting nitrogen concentration varies from year to year. Thus far, no trends have been discovered between vineyard management techniques and resulting nitrogen concentrations held in the grapes.

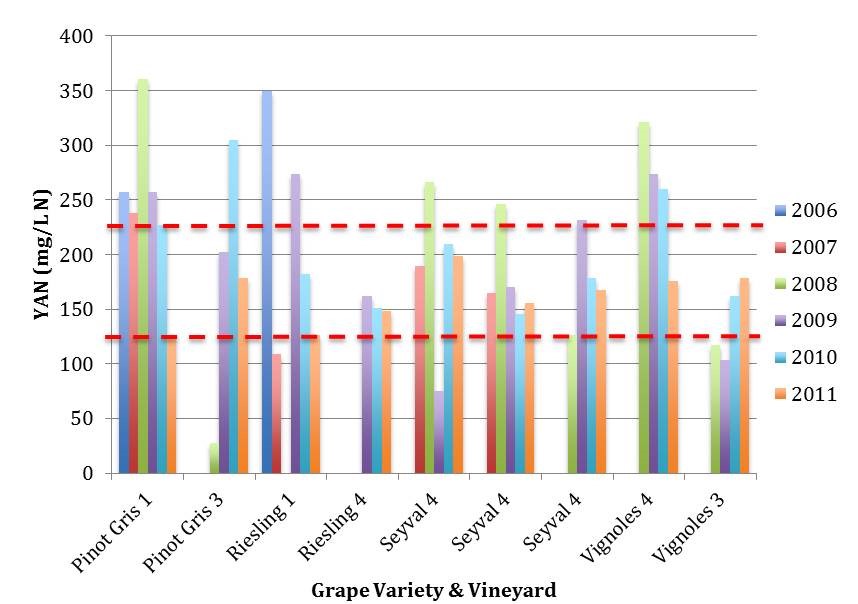

In 2012, I analyzed nitrogen data collected by a regional winery who had been storing yeast assimilable nitrogen (YAN) data they collected for over 6 years. The data was unique in that it tracked YAN concentrations from single varieties planted in single vineyard blocks over a large stretch of time. Not surprisingly, the data confirmed variation in nitrogen concentrations prior to fermentation on an annual basis (Figure 1).

What does this mean for winemakers?

With the current understanding of YAN, it cannot be predicted or even estimated. It’s something winemakers have to make time for if they are going to treat their fermentations appropriately.

The heaviest resistance associated with YAN is simply getting it analyzed. The investment for equipment to measure YAN can seem steep for smaller (<10,000 case annual production) wineries. Furthermore, the enzymatic analysis required for YAN measurements may seem complicated to an untrained individual. It’s also fairly time consuming compared to analyses like pH and Brix measurements.

For something that can minimize latent production issues and alter wine quality, addressing fermentation nutrition is something I recommend every winemaker consider as part of their fermentation plan.

What is YAN?

The abbreviation YAN stands for yeast assimilable nitrogen. ‘Assimilable’ is a French term, and I often hear YAN more regularly referred to as yeast available nitrogen among discussions in the U.S. This accounts for how much nitrogen is available to the yeast (and other microorganisms) at the start of primary fermentation.

YAN is contributed by two different nitrogen sources:

- Inorganic nitrogen, a contribution from ammonia ions, and

- Organic nitrogen, a contribution from amino acids.

Both forms accumulate in the grape berry through the ripening season.

Where does YAN come from?

As mentioned above, the primary source of nitrogen during fermentation comes from the fruit itself. YAN values change annually, resulting in differences from the vineyard site, growing season, vineyard management techniques, and wine grape variety. At two research vineyard sites I used to work with, there were about 30 wine grape varieties planted within an acre of land. Even within that one acre, YAN values ranged from low to high and everything in between.

Photo by: Denise M. Gardner

The second large contribution of YAN comes from additions made by the winemaker during primary fermentation. Again, both inorganic (in the form of diammonium phosphate, or DAP) and organic (usually sourced from what are known as “complex nutrients”) can be added to a fermentation through ingredient additions. These additions are often made to supplement fermentations, ensure optimal growing conditions for the yeast, and minimize off-flavor development.

Why is YAN important?

Without adequate nitrogen, the yeast cannot effectively grow, multiply, and carry out their primary metabolic functions. As covered previously, a lack of available nutrition can lead to stuck fermentations. A stuck fermentation can lead to additional problems including allowing time for spoilage microorganisms to grow and thrive as well as lead to off-flavor developments.

With both inadequate and way too much nitrogen, the risk of hydrogen sulfide development becomes more prevalent. While both situations require nutrient adjustments be made differently, care and consideration for how to treat the fermentation is required by the winemaker. It’s worth noting that hydrogen sulfide can arise even when a must is properly treated with nutrients. However, the incidence rate tends to drop with proper YAN analysis and tailored treatment.

It may be easy to justify not measuring YAN. After all, if hydrogen sulfide develops, the winemaker can easily treat the wine with copper sulfate to minimize the impact of that aroma. However, the consumer market has recently laid a heavy preference towards minimizing heavy metal concentrations in wine. As a side note, I encourage all of my clients to reduce residual copper concentrations through further fining. DG Winemaking clients can get access to these options and treatments in the Reducing Copper production guide for winemakers.

Furthermore, the addition of copper sulfate can often simplify the aromatics of wine, which may limit wine complexity. For some wine styles, this may not be significant. For others, the time and investment in measuring YAN, treating the fermentations accordingly, and avoiding hydrogen sulfide development is often worth it.

Further resources for making appropriate nitrogen adjustments during fermentation

It’s important to note that nutrient addition strategies are heavily researched and recommendations change over time. If you’re still practicing nutrient strategies that were recommended in the 1980’s, it’s possible that you could be the source of some of your fermentation problems, especially if you are having issues with stuck fermentations or hydrogen sulfide development.

If you struggle to understand how YAN is calculated, and how nutrient additions contribute to the YAN content, you can download my free YAN Calculation Worksheet. This worksheet will teach you to better understand how DAP, hydration nutrient, and complex nutrient additions contribute to YAN.

Enological product suppliers (e.g., Lallemand, Enartis, Laffort, etc.) usually update their nutrient addition strategies, specific for their products, annually. You can review these updates by downloading or receiving their current product catalogs.

I tend to alter from their recommendations slightly, customizing additions based on the winemaker’s preferred nutrient, the must chemistry results, and the fermentation parameters. DG Winemaking clients can reference additional recommendations in the Fermentation Nutrition Strategies production guide.