Malolactic fermentation (MLF) is tricky! The biological conversion of malic acid (naturally found in grapes) to lactic acid by lactic acid bacteria (LAB) is a finicky process that can resort in off-flavors, a sluggish process, or even spoilage. It’s up to the winemaker to really pay attention to several parameters to ensure that MLF completes in a timely manner.

Living LAB species, Lactobacillus, Oenococcus, and Pediococcus, carry out the MLF process (Krieger 2005, Iland et al. 2007). These bacterial species are native to the grapes, but it is most common to inoculate for MLF using a commercial Oenococcus oeni strain. Selecting the right O. oeni strain is important and can make the difference between MLF completion or failure.

Since we are at the height of MLF season, let’s review some of my top tips for ensuring MLF success.

Photo by: Denise M. Gardner

1. Select the Right Malolactic Bacteria (MLB) Strain

LAB have ideal temperature ranges and growing conditions for growth and metabolism, including the O. oeni strains commercially available for MLF inoculation. For many MLB strains, the wine and environmental temperature needs to be at least 58°F. Always double check strain details with the supplier. Winemakers should make sure that they can maintain the appropriate growth temperature for whichever MLB they select.

The LAB strain and MLF process can contribute significantly to the wine’s style. Most suppliers, today, highlight the degree of “buttery” flavor that is contributed by MLB. For white wine styles like oaky Chardonnays, selecting a strain that provides adequate “buttery” flavor is usually desired. However, for other white wine styles and for most red wine styles, this flavor contribution is not as desirable. Therefore, winemakers should take the time to ensure the flavor profile produced by their select strain matches the wine color and style they are targeting.

If co-inoculating (or co-fermenting) with primary fermentation yeast, winemakers must make sure the yeast strain and MLB strain are compatible. All suppliers offer this information for co-inoculation techniques in their technical material. Winemakers should also feel comfortable contacting technical sales to double check these details if needed. (Trust me, avoiding a phone call is not worth a stuck MLF. Sluggish and stuck MLFs are timely, frustrating, and often, expensive, situations.) If you are new to the world of co-inoculate or co-fermentation, refer to the Production Guide: Red Wine Production Diagram – Co-Fermentation, which details the operational order for this winemaking technique.

2. Monitor Wine Temperature during MLF

Many LAB strains require a temperature at or above 58°F to successfully grow and complete MLF. Of course, winemakers are encouraged to rely on supplier recommendations for the ideal growth parameters for their select strains. However, unlike wine yeast, LAB are prone to stress with temperature variations. Such stress can lead to sluggish or stuck MLFs.

This is also true with co-inoculation techniques in which the wine fermentation temperature (the temperature of the wine) must remain conducive for MLB growth.

If the wine temperature goes lower or higher than the ideal MLB temperature, this can cause significant hinderance to MLF progression. Therefore, it’s important for the winemaker to ensure a steady environmental and wine temperature during MLF. Winemakers can adequately monitor wine temperature using stainless steel temperature probes.

3. Reduce Oxygen for MLF Success

Minimizing oxygen is key to a successful MLF because O. oeni are facultative anaerobes. This means that they require little-to-no oxygen for growth. Comparatively, acetic acid bacteria, which are a natural part of wine/winery microflora, require oxygen for their growth and reproduction. Thus, winemakers that can minimize oxygen during the MLF process typically ensure the MLF bacteria will dominate the wine’s microflora during this process. Very few other wine microorganisms can survive and thrive under such low oxygen conditions.

How do we make this tip practical for winery operations?

- Make sure barrels are topped up during MLF and stored in appropriate conditions (i.e., temperature, reduction of oxygen by minimizing opening a barrel for the appropriate length of time) for MLF and barrel hardiness.

- Wine tanks that contain wine undergoing MLF should be topped up or blanketed effectively to minimize oxygen. If you are uncertain about appropriate blanketing procedures, reach out to expertise for sound advice.

- Avoid the use of plastic tanks/totes during the MLF process. Plastic allows for oxygen transfer, even if that transfer is slow, which can be detrimental to the MLF and allow spoilage bacteria to thrive.

4. Monitor the Wine for Large VA Increases

Measuring volatile acidity (VA) is the best indication that spoilage bacteria are out-growing LAB during MLF.

It’s normal to see some small (up to 0.2 g/L acetic acid) increases in VA during MLF. However, VAs that accumulate by 0.5 g/L or more during this time are an indication of spoilage. Specifically, this indicates that acetic acid bacteria may be dominating the wine’s microflora during this time in the wine’s production.

A significant increase in VA indicates that the winemaker should take action and avoid “waiting out” the process to see what happens. Instead, the winemaker usually needs to be proactive and get the MLF to thrive again.

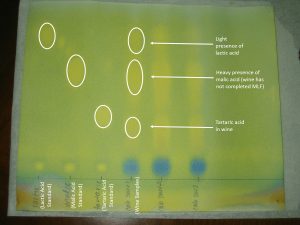

5. Confirming MLF Completion Is Key

While paper chromatography is a good MLF monitoring tool, it is not the greatest assessment for completion of MLF. Instead, winemakers should plan on having residual malic acid tested to ensure the concentration is <0.3 g/L (industry standard) or <0.1 g/L (technical dryness for MLF). Many wineries will have to send a wine sample out to a lab to get a malic acid concentration reading. Getting to these dry levels ensures the wine is less at risk for post-bottling refermentations.

Photo by: Denise M. Gardner

The Juice and Wine Analysis Recommendations outlines measuring malic acid at the end of primary fermentation. This measurement acts as a starting point to monitor MLF progress. Winemakers that wait to measure malic acid concentration mid-MLF have no starting indication of the malic acid concentration and cannot determine if the MLF process is sluggish or stuck.

Several wineries are now using the Sentia tool, which makes monitoring malic acid degradation more feasible for many winemaking operations.

MLF Completion is Essential

Why is MLF completion so essential? Without adequate analysis (i.e., malic acid concentration), the winemaker has no way of knowing if the MLF is dry. Dryness matters because:

- Many post-bottling fermentations are actually MLFs in bottle.

- Many bottled wines lack adequate free SO2 concentrations to ensure a spontaneous MLF does not take off in the bottle. (Remember, potassium sorbate additions do not inhibit MLB growth.)

- Many wineries (or mobile bottlers) lack adequate current Good Manufacturing Practices (cGMP) procedures to ensure and validate bottling sanitation. Thus, it is difficult for wineries to understand bottling conditions, including avoidance of bottle contamination with MLB.

- Many wineries blend wines that went through MLF with wines that did not go through MLF, which acts as an inoculation for the blend. If adequate filtration or sanitation controls are not in place, this situation can lead to post-bottling MLFs.

The bottom line is this: when it comes to MLF, it pays to be thorough.

The views and opinions expressed through dgwinemaking.com are intended for general informational purposes only. Denise Gardner Winemaking does not assume any responsibility or liability for those winery, cidery, or alcohol-producing operations that choose to use any of the information seen here or within dgwinemaking.com.