As COVID-19 continues to affect many regions across the U.S., winery operations may want to tackle planning for extra precautions to minimize the infection and spread of the virus within the production space. As we discussed previously, planning before infection becomes imminent is advantageous to employers.

Harvest operations have the primary advantage of typically taking place outdoors, which offers ideal environmental conditions for employee safety against viral spread. Though, as many researchers caution, being in proximity to sick individuals is a risk regardless of whether exposed individuals are indoors or outdoors (infographic, DesOrmeau, T. 2020 news article summary on experts’ risk evaluation).

However, additional precautions can be considered to maintain a healthy work environment under current COVID-19 infection risks. This can be especially important as wines begin to ferment in the cellar space and employees are brought indoors to interact with one another.

Entry into the Winery

Creating a protocol for entering the workplace and enacting it now before harvest begins may be advantageous.

An example for how this could look includes:

- Employee must arrive to work with a freshly laundered mask or new disposable mask, or be given a fresh mask upon arrival. Masks should be applied according to proper techniques, which I reviewed in the past COVID-19 Mitigation post on bottling.

- Have a handwashing station that employees must wash their hands upon entering the workplace according to proper techniques.

- Some employers are opting into health questionnaires or temperature screenings with employees arriving to work. I encourage wineries considering this step to discuss the implications of this with legal counsel prior to implementing the practice.

From here, employees adhere to wearing their facial covering except during meal breaks and until the end of the workday. If you need a review on the benefits of wearing a mask for the protection of those around you, I suggest the Science Vs. episode “The Mask Wars” available in audio and written form.

Assign Teams or Positions to Minimize Large Groups Working Together

One way to encourage social distancing and maintaining 6-feet of distance between employees is to plan out where equipment should get laid out during harvest and where employees should be in relation to that equipment. Consider using floor tape to mark the locations of both equipment and where employees should stand during harvest operations.

Additionally, pre-assign harvest roles. In smaller operations, it is not unusual for only 2 to 3 people to work on harvest operations at one time. To help maintain distances between them, assign who will do what task during a harvest day and role play how production will look during that time so that employees can get used to staying separated. Perhaps one person is on a forklift emptying bins of grapes into the crusher/destemmer while another employee is manually pulling out the grapes from the bin using a food grade shovel. The third employee may be further down the production line, monitoring the must pump or washing spent bins. This would be their assigned jobs during harvest to avoid overlap and grouping. However, make sure to have contingency plans should one or two individuals fall ill.

This is also a good time to not neglect how the winery’s lab operates. Most operations have a confined lab space for employees to work. Though, if the winery is planning on updating their laboratory for COVID-19 mitigation or for general upgrades, reviewing the lesson, “Fundamentals of the Winery’s Lab” is not a bad idea ($53 for an à la carte one-month purchase with written lesson notes) to get ideas for layout and essentials within the lab space. Again, assigning specific roles to the lab employees prior to harvest and then laying out those workspaces at least 6-feet apart can encourage employees to maintain proper distance requirements.

Consider Production Flow

If the name of the game is to maintain a safe distance, then planning out employee workflow is not a bad idea. After the grapes are harvested, usually there is tank and bin monitoring that takes place throughout the duration of fermentation.

Again, having two people assigned to this task at the same time is a physical safety precaution that should not be ignored. However, consider their interaction and workflow could contribute to health precautions. For example, a spotter at the bottom of a tank while an employee is at the top of a tank is not a bad idea, and employees can maintain a safe distance during this practice.

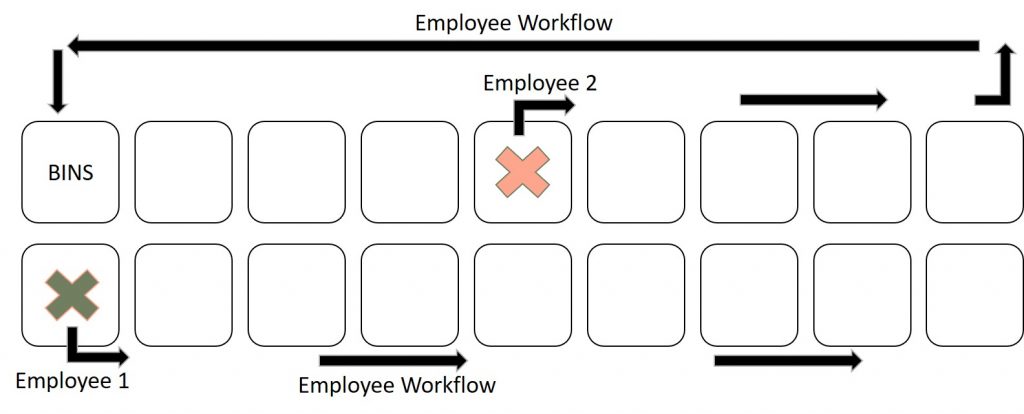

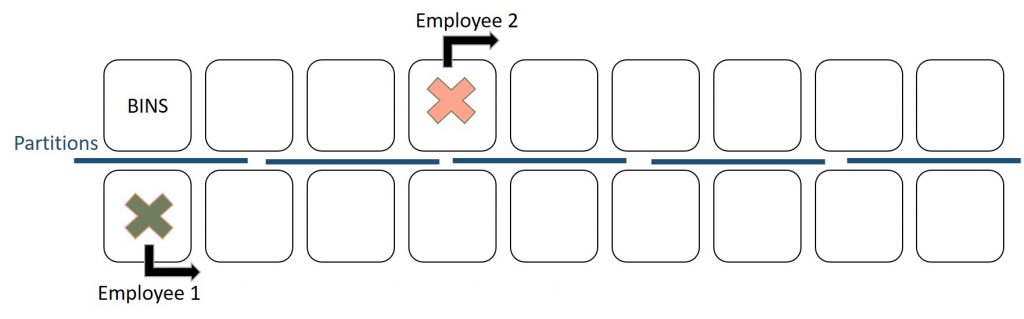

In contrast, if employees are doing a number of punch downs daily, consider assigning punch downs to two employees that can begin at different bin locations, maintaining an appropriate distance at all times. If bins are in a single file, one employee can start at an end while another in the middle, both working in one, uniform direction. If bins are in pairs, consider using mobile dividers that we previously discussed during bottling, or plan out how the employees will work through those bins while maintaining six-feet of distance between them at all times.

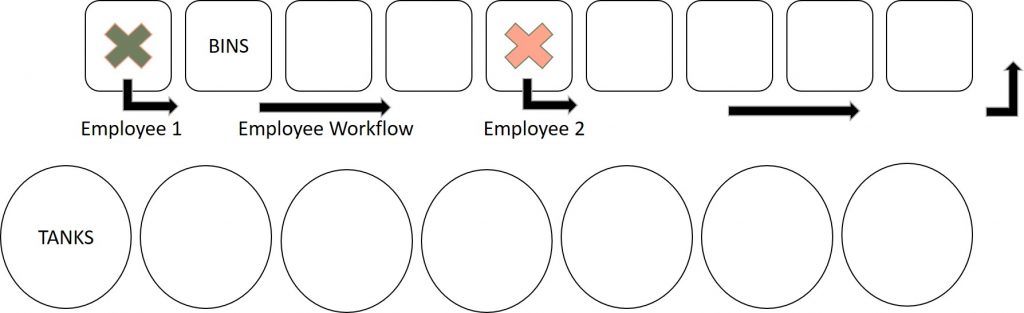

Figure 1: Example employee workflow when macrobins are lined in a single row and near a single row of wine tanks. Employees maintain at least 6-feet of distance apart from each other and move onto the next bin in the same direction.

Figure 2: Example employee workflow on macrobins that are aligned in side-by-side rows, and without partitions. Employees still maintain a safe working distance apart from one another and move onto the next bin in the same direction to avoid running into each other.

Figure 3: Example employee workflow on macrobins that are aligned in side-by-side rows with partitions.

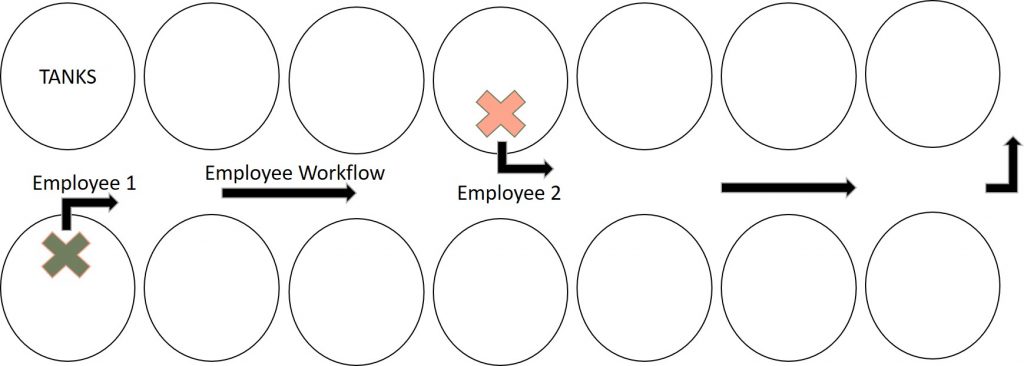

In some operations, and if space allows, reorganizing tank layout could be helpful. Again, having floor tape mark six feet of separation act as visual markings for employees to maintain a safe distance. Creating one-way flow, similar to how grocery aisles were altered, is also useful at managing employees’ interactions and can be implemented prior to the start of harvest so employees can get used to this change.

Figure 4: Example employee workflow in between two rows of tanks. Employees should make sure to always maintain a safe distance of at least 6-feet apart and move in a single, unified direction to avoid grouping.

Receiving Items and Winery Deliveries

It was interesting for me to hear Southern Hemisphere wineries talk about receiving items to the winery during the initial COVID-19 outbreak. Some would only receive deliveries on a schedule that had to be pre-approved. Many had delivery requirements, including:

- Assigning specific employees to work with deliveries. These employees often had their own set of requirements including wearing gloves, washing their hands after touching each delivery, and wearing a facial covering at all times.

- Requiring drivers to wear a mask or facial covering, and not allowing the driver to come into the production spaces.

- Implementing contactless agreements: having paperwork sent via email and accepting many deliveries “in good faith.”

I still remember one winemaker saying they “treated everything coming into the winery as if it could be contaminated with the virus,” which included people, objects, and raw materials like fresh grapes. At that time, researchers were referencing a March “Letter to the Editor” in the The New England Journal of Medicine that showed the potential for SARS-CoV-2 (Coronavirus that causes COVID-19) to exist on certain surfaces for up to 72 hours in some instances. This potential indirect contamination is not uncommon in the viral world, and other viruses have been noted to cause human infection through fomites, materials or objects that can carry infections (Sze-To et. al, 2013). Therefore, taking precautions and treating each incoming material as if it could be contaminated with the virus was not a bad precaution wineries and other food facilities took.

However, more anecdotal discussion surrounds less prominent transfer of SARS-CoV-2 (COVID-19) through fomites (ABA News, BfR Journal). However, until sound scientific evidence finds a lack of fomite transmission, it is a good idea to develop a receiving protocol for incoming supplies, how employees should handle packages/totes/etc., the expectations of delivery personnel, and proper handwashing etiquette. Therefore, developing a receiving protocol for packages, versus ingredient deliveries, versus raw materials (e.g., juice, grapes), could be beneficial for the winery as harvest season emerges.